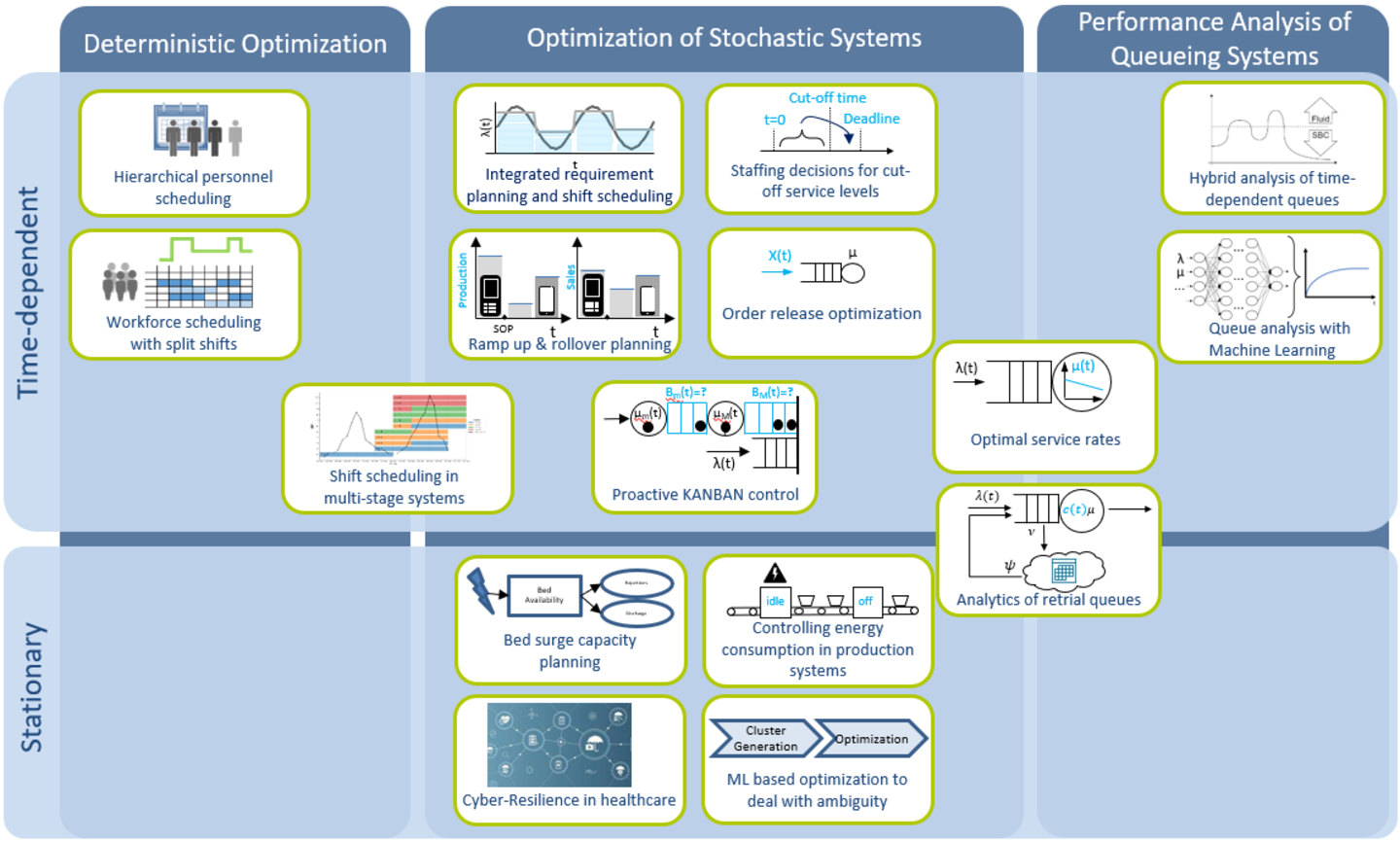

As shown in the figure below, several techniques from predictive and prescriptive business analytics, especially from Operations Research, are used to analyze and to optimize production and operations systems under static and dynamic conditions.

Current research projects are in three area i) operations scheduling, ii) management of dynamic systems, and iii) design of lean operations systems.

Operations scheduling

In this field, our focus is on scheduling operations in a multi-product setting, i.e., allocating heterogeneous jobs to (heterogeneous) resources. We consider both tactical and operational planning situations, for example with sequence-dependent processing or set-up times. Additionally, different aspects of fairness are considered, especially in workforce planning and task assignment.

Management of dynamic systems

Another stream of our research is related to tactical and strategic planning of capacity under unceratain and time-dependent demand and service level restrictions. In this setting, production processes are often highly time-dependent, e.g., due to the influence of capacity ramp-ups, seasonal demand patterns, or time-dependent reliability. We support diverse managerial decisions in such stochastic and time-dependent environments.

Design of lean operations systems

This research area is related to the analysis and optimization of the performance of manufacturing systems under stochastic conditions, e.g., due to uncertain supplier's capacities, machine breakdowns, or customer demand variability. The aim is to support decisions in the strategic configuration of lean production systems that are robust with respect to planned and unforeseen changes.

The corresponding application areas are broad with projects in Industry 4.0, airport operations, automotive production, workforce planning, or management of distribution centers. Some projects are funded by industry partners, the European Union, or the German science foundation (DFG):

- Performance analysis and capacity planning for stochastic systems with cut-off service levels (Funded by Deutsche Forschungsgemeinschaft e. V. in Collaboration with Karlsruher Institut für Technologie) (2020 – 2022)

- Productive 4.0 – Analytical approaches for performance evaluation and optimization of stochastic and dynamic processes in digital production (Funded by European Union and Bundesministerium für Bildung und Forschung in Collaboration with over 100 academic and business partners. (2017 – 2020)

- Scheduling in multi-stage systems with time-dependent demand (Funded by Deutsche Forschungsgemeinschaft e. V. in Collaboration with Karlsruher Institut für Technologie) (2018 – 2020)

- Integrated maintenance and production scheduling of multipurpose process plants (Funded by ABB AG) (2015 – 2016)

Ongoing PhD projects

- Tim Weber: Quality‐speed trade‐off in time‐dependent queueing systems

- Ömer Özümerzifon: Performance analysis of time-dependent retrial queues

Finished PhD projects

- Dr. Seyed Mohammad Zenouzzadeh: Enhancing Operations Management through Descriptive, Predictive, and Prescriptive Analytics (2025)

- Dr. Johannes Diefenbach: Design and control of stochastic manufacturing systems (2022)

- Dr. Amir Foroughi: Three Essays on Algorithmic Approaches in Operations Management (2022)

- Dr. Jannik Vogel: Capacity plannning in stochastic and time-dependent operations systems (2019)

- Dr. Annika Becker: Three Essays on Optimization Models in Manufacturing and Service Industries (2018)

- Dr. Gregor Selinka: Three Essays on the Performance Evaluation of Queueing Systems with Time-Dependent Parameters (2016)

- Dr. Hendrik Guhlich: Bid price-based revenue management approaches in manufacturing industries (2016)

- Dr. Emilio Zamorano: Three essays on workforce scheduling (2016)

- Prof. Dr. Justus Arne Schwarz: Analysis of buffer allocations in time-dependent and stochastic flow lines (2015)

- Dr. Alexander Lieder: Three essays on operations scheduling with job classes and time windows (2015)

- Dr. Sophie Weiss: Optimization of buffer allocations in stochastic flow lines (2015)